Mineração Usiminas

Produzir e comercializar minério de ferro de qualidade com segurança e respeito ao meio ambiente é o nosso compromisso.

Quem Somos

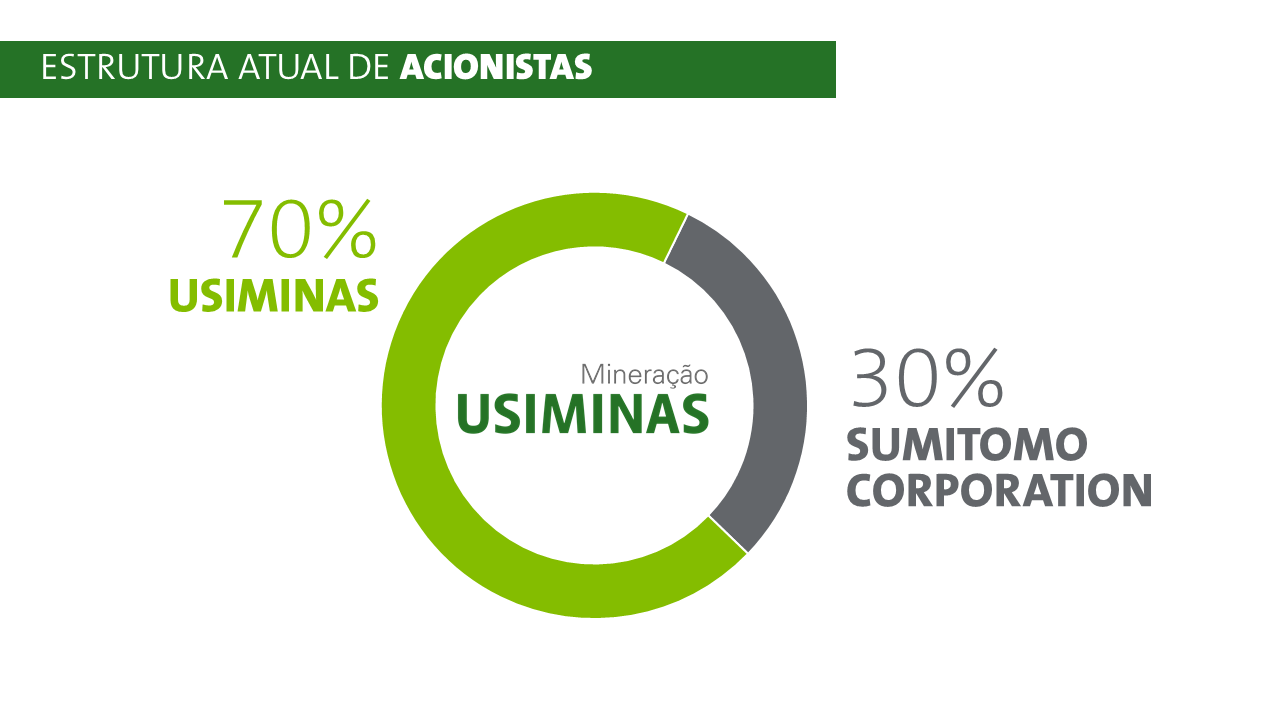

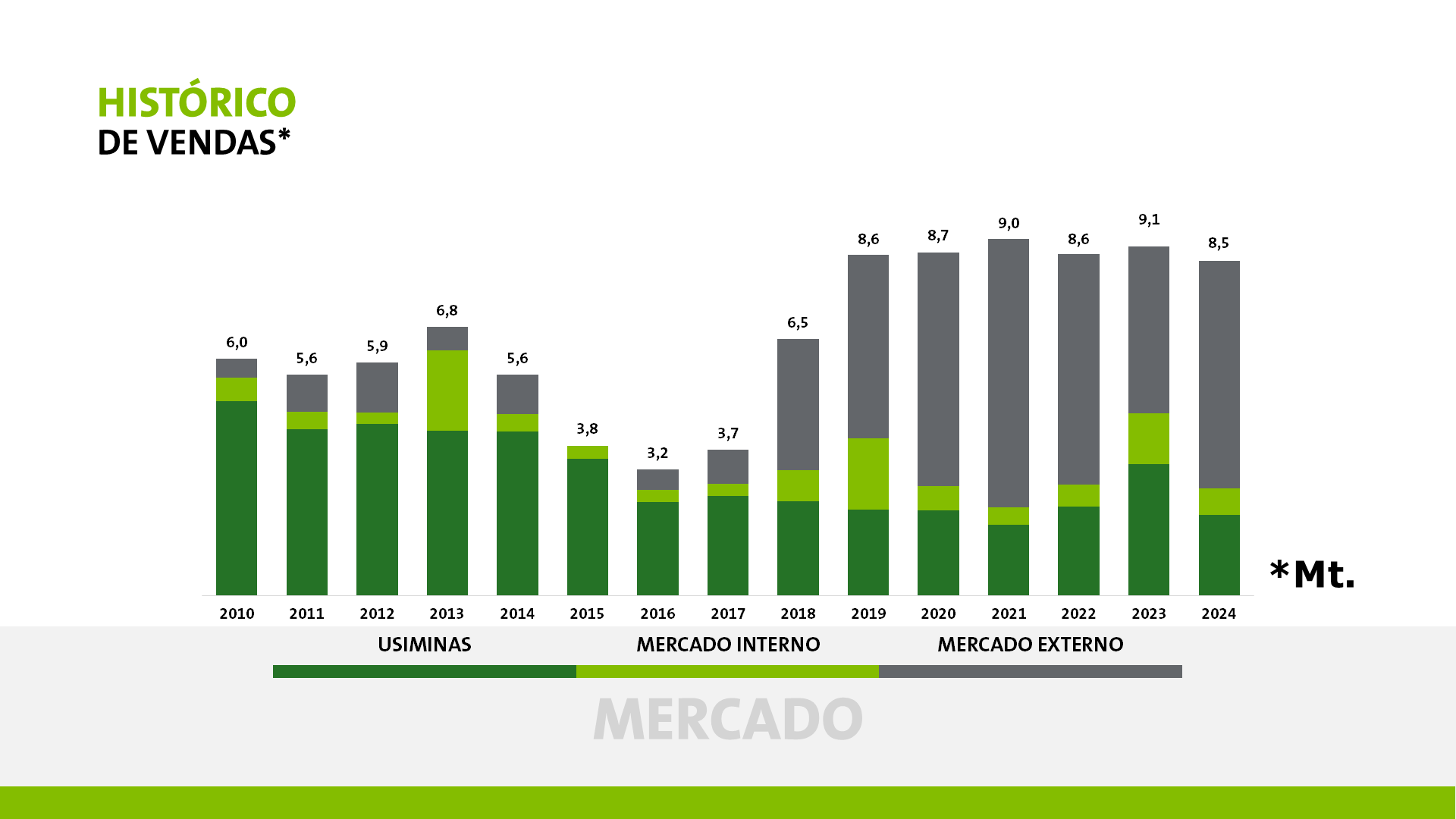

A empresa nasceu de uma joint venture entre a Usiminas e o grupo japonês Sumitomo Corporation, em 2010. Se no início das operações o foco era atender às demandas da própria Usiminas, atualmente a MUSA se posiciona como importante fornecedora de minério, tanto para o mercado nacional quanto para o mercado internacional.

minério de alta qualidade, usando inovação e tecnologia, sem abrir mão da segurança e do respeito ao meio ambiente. Esses são alguns dos principais objetivos da Mineração Usiminas S/A (MUSA).

Governança Corporativa

Carlos Héctor Rezzonico

Chief Executive Officer - CEO

Hiroyuki Matsumoto

Diretor de Desenvolvimento

Marcelo Héctor Barreiro

Chief Financial Officer - CFO

Demonstrações financeiras

Clique e confira as Demonstrações Financeiras de 2024 da MUSA.

Clique e confira as Demonstrações Financeiras de 2023 da MUSA.

Clique e confira as Demonstrações Financeiras de 2022 da MUSA.

Clique e confira as Demonstrações Financeiras de 2021 da MUSA.

Clique e confira as Demonstrações Financeiras de 2020 da MUSA.

A história da Mineração Usiminas

Foco no cliente

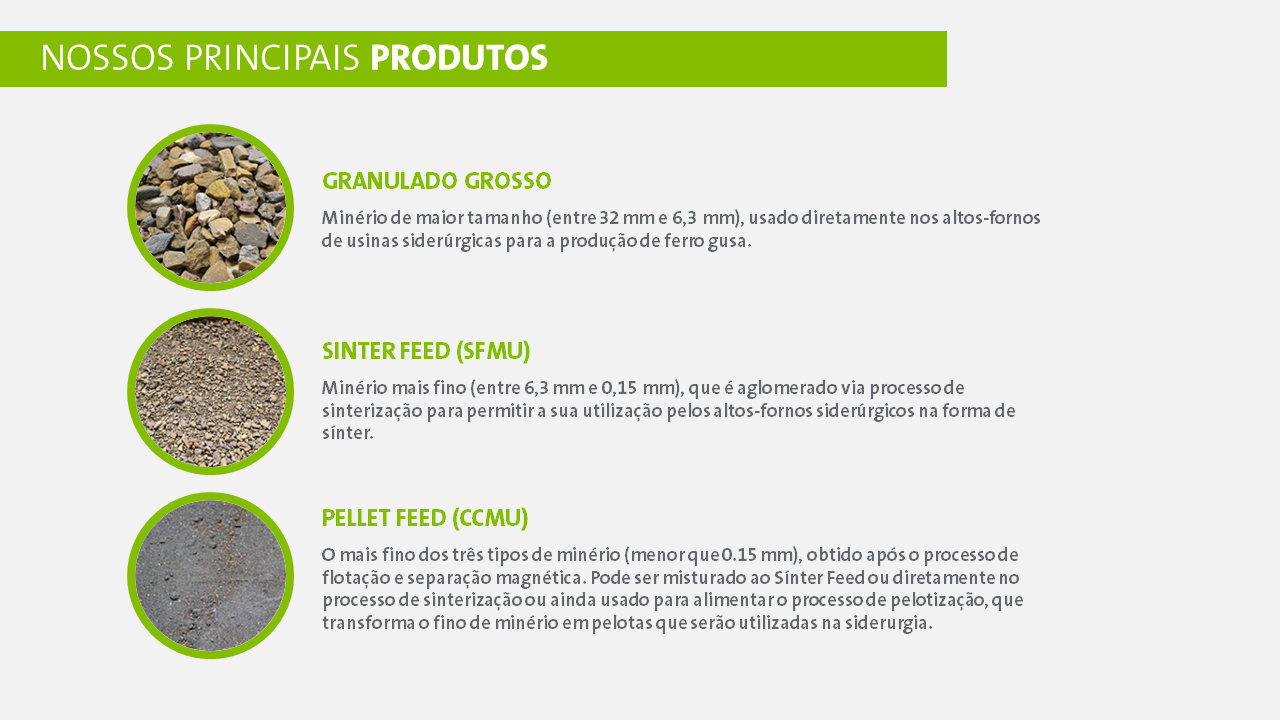

Produtos

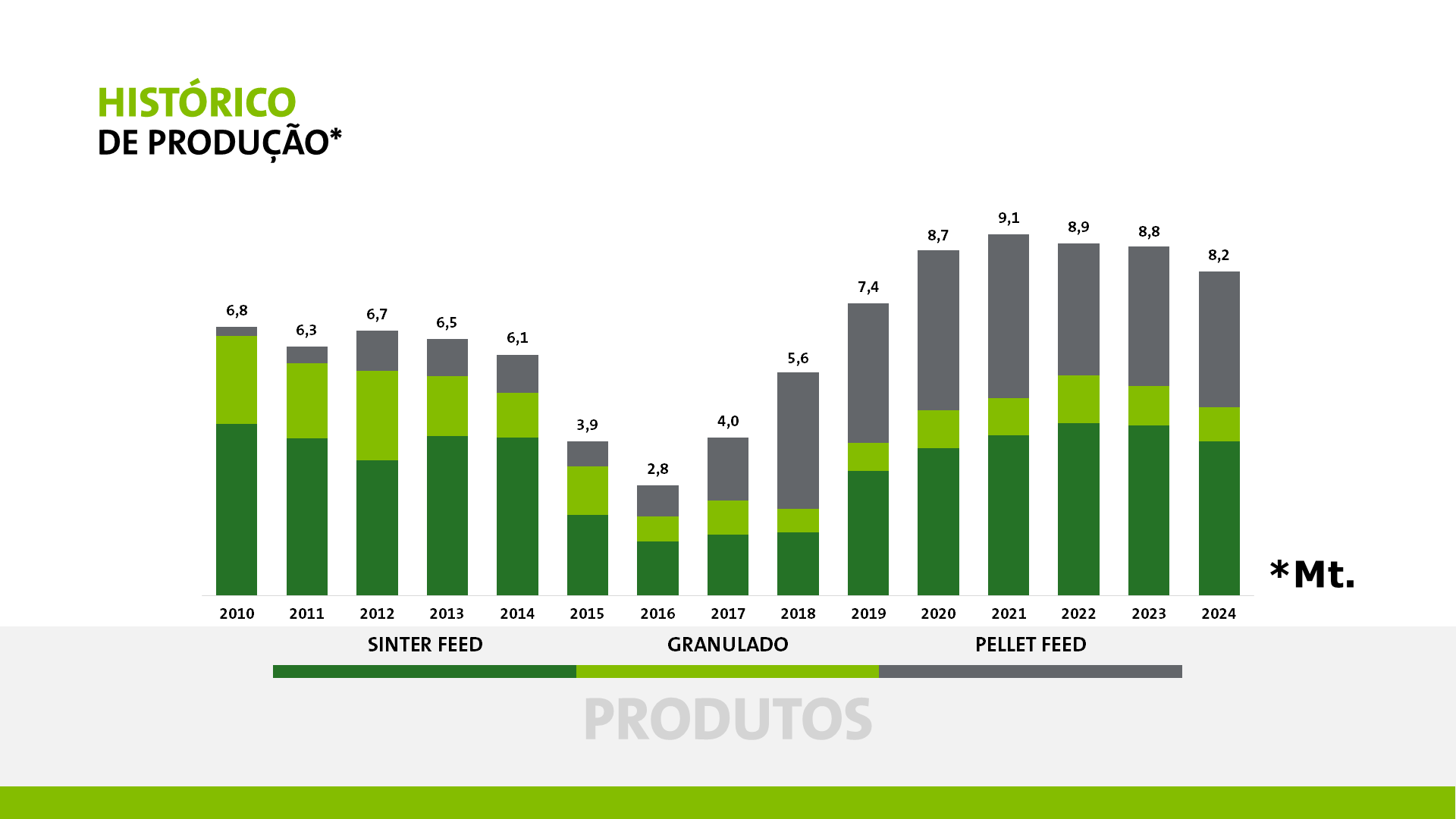

Entre os anos de 2015 e 2017, o setor de mineração sofreu com os impactos da crise econômica que causou queda no consumo e no preço do minério de ferro

Entre os anos de 2015 e 2017, o setor de mineração sofreu com os impactos da crise econômica que causou queda no consumo e no preço do minério de ferro

A presença da Mineração Usiminas hoje

Trabalhe conosco

Comunidade

As comunidades da região de atuação da Mineração Usiminas têm ampla abertura para o diálogo com a empresa. São realizadas reuniões frequentes com os moradores do entorno da unidade, para levar a eles informações importantes, além de ouvi-los, com abertura para esclarecimento de dúvidas, críticas e sugestões. A Mineração Usiminas integra a Associação das Mineradoras da Serra Azul (AMISA). E junto das demais empresas que fazem parte da instituição, desenvolve ações voltadas às comunidades, com foco na transparência e no desenvolvimento sustentável da região. Confira as ações e canais de relacionamento da MUSA com a comunidade:Projetos de Responsabilidade Social

Realização de dezenas de projetos sociais, culturais e esportivos nos municípios de atuação da empresa por meio do Instituto Usiminas.Time de suporte

Um time de suporte foi colocado na zona de autossalvamento para ajudar moradores com deficiências em caso de situação de emergência nas barragens.Histórias da Mineração

Programa de visitas de familiares de colaboradores, comunidades, organizações e escolas da região para conhecerem o processo de mineração de um jeito informativo e lúdico.

Fale conosco

Ligação gratuita por meio do 0800 979 79 70 ou contato pelo e-mail faleconosco.mineração@usiminas.com para tirar dúvidas e fazer reclamações e pedidos.Fala Aí, comunidade!

Canal de WhatsApp para comunicação rápida e direta com as comunidades. Envie um WhatsApp para (31) 9.8395-3435.

Voluntários Usiminas (VOU)

Programa de voluntariado corporativo com a participação de colaboradores (as) nas ações em prol do desenvolvimento social das comunidades.

Mentoria Plano de Vida

Voluntários da Mineração Usiminas compartilham conhecimentos e experiências com estudantes da rede pública de ensino, visando contribuir para o desenvolvimento e a formação para o mercado de trabalho desses jovens.Principais projetos

Sistema de Disposição de Rejeitos Filtrados

Em dezembro de 2021, a Mineração Usiminas inaugurou, em Itatiaiuçu, o Sistema de Disposição de Rejeitos Filtrados (Dry Stacking). A nova planta permitiu à empresa encerrar o ciclo de uso das barragens para a disposição dos rejeitos gerados no processo de beneficiamento de minério.

Com investimentos da ordem de R$ 235 milhões, a planta de filtragem é totalmente conectada ao processo de beneficiamento. O valor investido também engloba a preparação da área que recebe os rejeitos, formando uma pilha, e o transporte do material entre os dois pontos.

Compactos

Em fase avançada de estudos de viabilidade, o Projeto Compactos busca perenizar as atividades e a produção das minas na unidade, em Itatiaiuçu. O eixo principal do projeto é a explotação de minérios mais pobres, diversificando o modelo atual de extração da Mineração Usiminas.Em dia com o meio ambiente

Para a Mineração Usiminas, tão importante quanto oferecer minério de qualidade é garantir que as nossas operações estejam alinhadas com as melhores práticas ambientais. Com esse foco, a área de preservação da MUSA é aproximadamente 4,25 vezes maior que a área de operação da empresa. A taxa de reuso da água nas nossas operações foi de 92,5%, em 2020.

Atuar com foco no desenvolvimento sustentável de Itatiaiuçu e região é compromisso da Mineração Usiminas, que desenvolve diversos projetos nesse sentido.

Alguns destaques:

Mina D´Água

Iniciado em março de 2021, o projeto Mina D´Água tem o objetivo de ampliar a proteção às nascentes, aos córregos e matas ciliares de Itatiaiuçu e região. A iniciativa consiste no mapeamento e na sistematização de um plano de recuperação da vegetação nativa em Áreas de Preservação Permanente, com isolamento do local por meio de cercamento e plantio de mudas de espécies nativas.

A empresa já possui 15 mananciais mapeados (em suas áreas protegidas) e que integrarão o Projeto Mina D´Água. E o compromisso é ampliar esse número, a partir do mapeamento das nascentes e cursos d´água em terrenos da companhia nos municípios de Itatiaiuçu, Mateus Leme, Itaúna, Rio Manso e Brumadinho.

Pegadas da Serra Azul

Onças-pardas, lobos-guarás e jaguatiricas, que vivem nas imediações da unidade estão sendo monitorados pela Mineração Usiminas desde outubro de 2020.

O objetivo é pesquisar, entender o comportamento e conservar esses animais em seu habitat natural, contribuindo para a preservação das espécies.

A iniciativa faz parte do Programa de Monitoramento da Fauna, desenvolvido pela empresa desde 2012 e que agora conta com a tecnologia para o alcance de melhores resultados. O uso de colares de GPS colocados nos animais é uma das inovações na realização desse trabalho.

Programa de Educação Ambiental (PEA)

A Mineração Usiminas (Musa) desenvolve o Programa de Educação Ambiental (PEA) com ações de conscientização junto ao público interno e, também externo, em parceria com a Associação das Mineradoras da Serra Azul (Amisa).

O PEA é composto por campanhas, cursos e oficinas, sobre temas diversos relacionados ao papel de cada pessoa na construção de um futuro melhor para todos. E por meio do programa, foi criada na empresa uma horta comunitária, cultivada com apoio do Grupo de Facilitadores Ambientais. Toda a produção é destinada aos colaboradores e colaboradoras.

Compromisso com a segurança e a sustentabilidade

A área onde ficava a barragem, após as obras de descaracterização e a revegetação, com o plantio de 12 mil mudas de espécies nativas.

A descaracterização da Barragem Central oficializada pela Fundação Estadual do Meio Ambiente (Feam) em maio de 2022 significou o fim das barragens a montante na Mineração Usiminas.

O processo para descaracterizar a Barragem Central foi iniciado em 2014, quando a Mineração Usiminas começou a lavra dos materiais depositados na estrutura, com reaproveitamento a partir do beneficiamento na Instalação de Tratamento de Minério (ITM) Flotação. Entre 2021 e 2022 foram realizadas as obras de descomissionamento/descaracterização e revegetação do local, que permitirá à área ser reintegrada à natureza.

As obras foram executadas de forma inovadora, dentro dos mais rigorosos padrões técnicos e, ao fim, foi feito o plantio de 12 mil mudas de espécies nativas. O trabalho continua com o monitoramento do crescimento da vegetação.

Metas ESG

Com a conclusão da descaracterização das barragens, a Mineração Usiminas cumpre mais uma das suas metas ESG (Ambiental, Social e Governança). Outra estrutura construída pelo método de alteamento a montante era a Somisa, descaracterizada em janeiro de 2021.

O encerramento do uso das barragens para disposição de rejeitos era outro compromisso firmado pela companhia e cumprido em dezembro de 2021. Isso foi possível com a inauguração da planta de filtragem, o Dry Stacking, e a desativação da Barragem Samambaia 0.

Centro de Controle Integrado

A segurança das operações e das comunidades é prioridade para a Mineração Usiminas e um bom exemplo é a completa reformulação do Centro de Controle Integrado. A tecnologia de ponta utilizada por equipe capacitada permite o acompanhamento das operações 24 horas por dia.

Equipamentos modernos garantem aos técnicos melhor visualização das áreas estratégicas e de movimentações em quaisquer estruturas. Ao todo, são 42 monitores e três painéis, que mostram, em tempo real, todos os processos da Mineração Usiminas.

Simulado externo

Em 2022, a Mineração Usiminas realizou, em parceria com as demais empresas que integram a Associação das Mineradoras da Serra Azul (AMISA), o II Simulado Externo de Emergência de Barragens. A iniciativa envolveu moradores de Samambaia, Curtume, Quintas do Itatiaia, Pinheiros, Lagoa das Flores, Retiro Colonial, Capoeira de Dentro e Vieiras, com grande apoio da população, poder público e agentes de segurança. O exercício seguiu o procedimento de Alerta e Preparação de Comunidades para Emergências Locais (APELL) da Organização das Nações Unidas (ONU) com regulamentadores rígidos para a execução e simulou a situação hipotética de acionamento do nível 3 de emergência de sete barragens ao mesmo tempo. O simulado externo faz parte do Plano de Ação de Emergência para Barragens de Mineração (PAEBM).

Acesso às informações

Para manter as comunidades bem-informadas sobre segurança de barragens são realizadas diversas atividades ao longo do ano. Como, por exemplo, os Seminários Orientativos/Reuniões Públicas, em parceria com as demais integrantes da Associação das Mineradoras da Serra Azul (Amisa). Essas são ações continuadas e é muito importante a participação dos moradores de todas as localidades envolvidas que, por meio dos encontros periódicos, recebem atualizações sobre programas desenvolvidos com foco na segurança e medidas que devem ser adotadas se houver emergência.

Confira as informações sobre as barragens da Mineração Usiminas:

Em maio de 2022, a Mineração Usiminas recebeu da Fundação Estadual do Meio Ambiente (Feam) o certificado de descaracterização da, até então, Barragem Central. A estrutura de disposição de rejeitos era a última construída a montante na empresa.

As obras foram executadas de forma inovadora, dentro dos mais rigorosos padrões técnicos. A revegetação permitirá à área voltar à forma original, ou seja, será reintegrada à natureza como era antes. No local, hoje conhecido como Parque Central, já foram plantadas 12 mil mudas de espécies nativas e o trabalho continua com o monitoramento do crescimento das mesmas.

A antiga Barragem Somisa, edificada pelo mesmo método de alteamento, foi descaracterizada oficialmente em janeiro de 2021.

A descaracterização das barragens a montante representa mais um compromisso cumprido pela Mineração Usiminas com a segurança e a sustentabilidade das operações!

Fim do uso de barragens

A Mineração Usiminas encerrou o ciclo de uso de barragens para a disposição dos rejeitos gerados no beneficiamento do minério de ferro. A última estrutura em operação era a Samambaia 0 - construída a jusante - que desativada em dezembro de 2021.

- Atendimento a Lei Estadual 23.291/2019

Resultados das análises e dos acompanhamentos do grau de umidade e do nível da barragem, com a respectiva ART

Análise semestral da água e da poeira dos rejeitos, com a respectiva ART

- Declaração de condição de estabilidade das barragens

Declaração de condição de estabilidade – Dique Oeste

- Plano de Ação de Emergência de Barragens (PAEBM)